Aluminium extrusions getting powder coated There are actually very specialized operations that use powder coatings of fewer than thirty μm or that has a Tg below 40 °C in an effort to create easy slender movies.

So, with that in mind, Here are a few guidelines to assist you get there and take advantage of out within your powder coating process.

Mechanical usually means is the easiest way—Which means sandblasting, sanding, or some sort of gross removing procedure.

Ultimately, it is essential that engineers take into consideration choice coating techniques as powder coating may well not constantly be the best choice. Though powder coating gives exceptional sturdiness and a sleek complete, other procedures including anodizing and classic portray may be a lot more Price-helpful with regards to the substance and its use.

Powder coating is usually suitable with many producing processes, such as laser chopping, die reducing, and CNC machining, due to the finish’s ability to resist precision and intricate perform. Having said that, powder coating is a lot less ideal for non-conductive products which include Wooden, which can not keep an electrical cost.

Innovations in powder coating technology have introduced special effects such as metallic and color-altering finishes that improve the aesthetic attractiveness of coated pieces. Metallic coatings mimic the glance of metal in a significantly reduced cost and body weight, earning them appropriate for decorative things and fixtures that have to have a metallic physical appearance with no have to have for metal building.

TIGER Drylac® has combined our 3D Metallic technologies with our Collection 138 item chemistry to create a new line of flex-get rid of metallics.

Whether for useful or decorative reasons, powder coating features an answer for enhancing the overall performance and appearance of innumerable goods and constructions.

Mechanical Pretreatment for Challenging Contaminants: Mechanical pretreatment includes the usage of abrasive media which effectively indicates rubbing or grinding to shine or clear a substrate. For selected programs the place inorganic contaminants like rust, mill scale, and laser oxide will need removal, this pretreatment process is favored. Strategies like sand or shot blasting las vegas metal finishing use high-velocity air to travel abrasive components (like sand, grit, or metal shot) towards the substrate.

Many thanks Valuable one Not Beneficial 1 Powdercoating is undoubtedly an environmentally friendly, corrosion and UV gentle resistant end. Even though it is most effective carried out with precision industrial products, it can be done to experiment with it in a house workshop.

Discharges throughout small distances between billed surfaces and ground can incorporate ample Strength to ignite the powder getting sprayed from the gun, even further emphasizing the protection element.

Drying: Effectively dry the substrate to prevent the development of h2o places or area defects within the powder coating. Air drying, oven drying, or pressured air drying can be used, based on the substrate and facility’s abilities.

The powder coating method enhances the aesthetic and longevity of solutions, making it a really perfect option for different producing purposes.

four. Plastic: Powder coating on plastic substrates is an additional modern method. It boosts the sturdiness and scratch resistance of plastic supplies while delivering a visually captivating end.

Michael Bower Then & Now!

Michael Bower Then & Now! Molly Ringwald Then & Now!

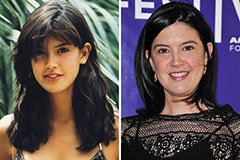

Molly Ringwald Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!